The resin sand molding is carried out in two departments:

A) Flaskless molding:

for castings from 50 to 500 kg medium/large series. For resin sand molding the “self-hardening” no-bake process

is used. The sand is agglomerated using a continuous mixer with furan-phenolic resin+ acid catalyst (p-toluenesulfonic acid).

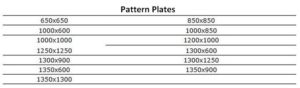

Dimensions of the pattern plates:

B) Hand molding:

for castings up to 3000 kg and sizes up to 2000×3000 mm with a self-hardening (no-bake) process.